How to choose metal profiles for roof tiles. 6 key aspects to pay attention to

Metal profile roofing has been very popular for years among building owners, builders and architects. The range of metal profiles available is becoming increasingly interesting and the choice is huge. Manufacturers offer tile metal profiles in trendy colours and shapes. They are an excellent alternative to ceramic tiles. When deciding on this type of coating, let us look at a number of aspects that can affect its durability. Check which metal tile profile to choose.

Metal roof profiles are valued mainly for their cost-effectiveness and versatility of quality, as they fit easily into different types of architecture. Aesthetic and architectural values are the most important factors in our purchasing decisions. We also need to take a closer look at the main technical characteristics.

In this article you will find out:

- Which metal tile profile to choose

- Choose a metal tile profile that is resistant to weather and mechanical damage

- Check which steelworks the steel comes from and where the metal profile itself is made

- Check the warranty conditions for the metal profile

- When choosing a metal tile profile, take into account the height of the terrain

- Which metal tile profile to choose. Effective coverage width

- Which metal tile profile to choose for a particular roof shape

Which metal tile profile to choose

If you are wondering which metal tile profile to choose, use the tips below!

Choose a metal tile profile that is resistant to weather and mechanical damage

For a roofing sheet to be durable and to optimally protect the house, it needs to be correctly selected according to the weather and the location of the building. Roofing is exposed to sun (UV radiation), temperature, chemical factors, seaside salinity and even mechanical damage such as cones falling from trees or maintenance work. Therefore, before choosing metal profiles for roof tiles, check which protective layers (coatings) were used in the production process of the metal sheets and profiles. The thickness and quality of the coatings are important for the durability of the coating.

One of the most popular coatings is Polyester Standard, the so-called "gloss" coating sheets, galvanised on both sides. If you want your roof to be more resistant to corrosion, it is worth looking at products that use this latest solution. Another coating that offers high resistance is Colorcoat HPS200 from TATA Steel, where a metallic layer (a mixture of 95% zinc and 5% aluminium) is responsible for protecting the base material. It also protects the cut edges of the sheet metal, which are particularly vulnerable to corrosion. The organic coating has a thickness of 200 µm, which guarantees excellent colour fastness, very high resistance to scratches and mechanical damage.

Check which steelworks the steel comes from and where the tile profile itself is made

To make sure that the material you buy is of the highest quality, let's check whether the tile profile manufacturing company you choose buys steel from the market leaders. Ideally, these should be products from reputable steel mills that sign their name and have worked for many years in their current industry (e.g. thyssenkrupp Steel Europe or TATA Steel).

Check the warranty conditions for the tile steel profiles

Usually lasting about 10-15 years. However, we will find offers on the market that are covered by a 60-year warranty. If we are building a house that will last for generations, we should choose such products. Equally important are the warranty conditions for the roof metal sheets or profiles. They are guaranteed by the manufacturer on condition that the metal sheets or profiles are stored, transported, handled and protected properly for a certain period of time. Correct installation is also important. Deformation and mechanical damage may invalidate the roofing guarantee. This is why it is so important to choose professional contractors who, in addition to proper roof installation, also offer roof service work (so-called audits - maintenance, cleaning, etc.). Knowledge of the correct installation and movement of the roof is key.

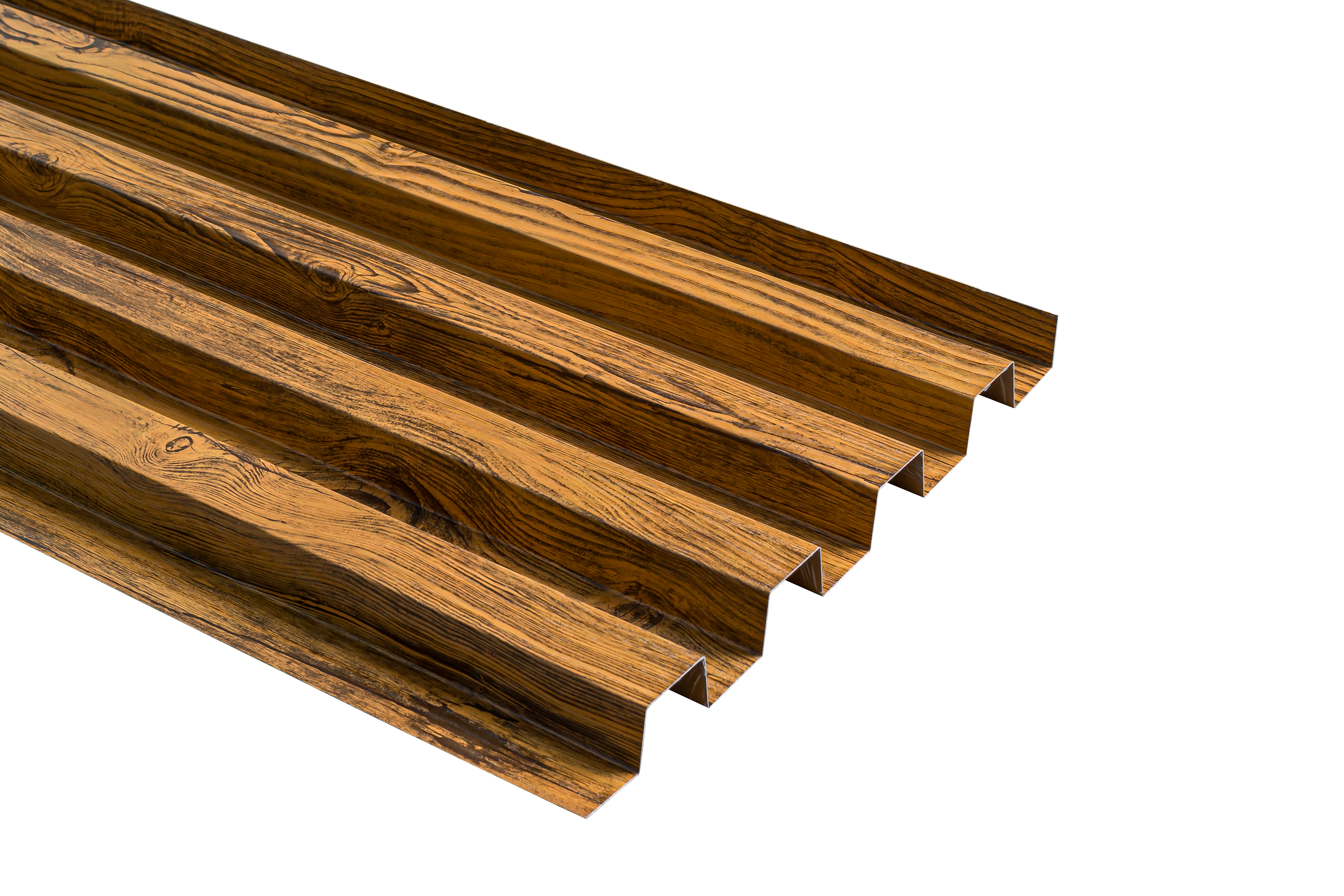

When selecting a metal tile profile, take into account the height of the terrain

Tiled metal profiles with high and many ribs look very plastic and are more rigid than those with a lower wave. Some manufacturers of tile pro files offer single, double and even triple ribbed products. It can have different shapes and heights, expressed in millimetres. And although such sheets usually have a smaller overlap width, which makes them more expensive, they improve the tightness of the roof and allow water to drain more quickly.

Which metal tile profile to choose. Effective coating width

When checking the technical characteristics of a particular model of metal roof tile profile, pay attention to the overall width of the sheets and the effective coverage width. These two parameters differ from each other and their value is determined by several factors. When selecting a sheet metal roof model, let us focus on the second parameter. This is the overall size reduced by the overlap width of the sheet or profile to create a tight and durable connection. It also allows the calculation of the actual quantity of tile metal profiles to be used for the entire roof covering.

Which tile metal profile to choose for a particular roof shape

The shape and complexity of the roof covering is also a factor in the choice of the particular tile profile and its type. For simple structures, it is worth choosing tile profiles cut to the pitch of the roof. For complex roofs, where the sheets require many cuts, it is worth using tile metal profiles in the form of patterns. The small size and the possibility of shortening by placing the profile under the previous one prevents waste.